I always wanted a tractor

07/02/23 11:56

My grandparents were dairy farmers and one of the things I loved to do as a child was to stay on the farm, it was so much fun and has left me with many wonderful and valued memories of my grandparents and farming. Of course the reality was that it was a whole lot of very hard work for my grandparents but for me staying on the farm over school holidays it was just fabulous. Working in the dairy, cutting the grass around the house with a scythe (that kept me busy for a while…), helping grandpa sow seed - ie. operating the old mechanical levers on the wooden seeder and filling up the seed hopper as we went along was a boys own adventure, I loved it.

But that was over 40 years ago, the farm was sold back in the 1970s and my grandparents have long left this mortal coil. However I'm now living close to where the farm was and have my own little piece of paradise in the Brisbane Valley, it's not a lot but it's my lot. The block was really just a small slice of a paddock when I bought it in 2016, with grass over a meter tall and scrubby trees which I suspect had been seeded by birds flying over. The block is quite steep and the paddock grass was thick, woody and tough to cut so I decided to buy a tractor - just the excuse I needed to fulfil a boyhood dream. The block would have been too much for a typical ride on mower to handle and, I rationalised, the range of implements I could add to the tractor made it much more useful and more logical choice. Enter Rupert, my Kubota L1501DT tractor. (I named it Rupert because it looks like it comes from the Isle of Sodor.)

When I bought the tractor I was told everything works, "I just got the indicators working recently." In reality that was not so true, the indicators didn't work, although that doesn't bother me. The things which didn't work but which I really wanted to were: the tacho/hour meter, the charge light was always on, as was the oil warning light. This particular machine seems rather unique in Australia as the writing on the dash is in Japanese and the controls/layout are quite different from just about every other L1501 I've seen, plus no-one I've spoken to has ever seen one the same - not inspiring when you're trying to troubleshoot problems. Rather than a lever to the right of the seat to operate the three point linkage this model has a toggle switch on the dash for raising/lowering. Annoyingly the fuse for this switch kept blowing so I soon learnt to carry a box of spare fuses in my pocket just to get through the two hours of slashing I needed to do.

I searched for wiring diagrams, without much joy, and eventually thought I'd remove the fuse box and check all the wiring. It was then I discovered the fusebox had been installed upside down - this answered a few questions right away. I suspect the incorrect installation was leading to some shorting and once installed the correct way around my blown fuse problem disappeared, thankfully. However later the mechanism failed to operate at all, I traced the problem to a bad earth and resolved the issue by running a new earth wire to the rear of the tractor - nothing like dodgy wiring to ruin your day. By the way it was a bad earth issue with the wiring to the alternator causing the charge light to always be on, sorted that one early on to avoid draining the battery unnecessarily. Resolving some of the other issues meant buying some new parts and it was then that I discovered my L1501DT is a 'grey import', meaning this was not a model Kubota Australia imported into the country and their policy is not to support or supply parts to grey import tractors. I didn't know anything about this 'issue' when I bought the tractor, I just went looking and bought something which suited my needs. As far as I was concerned surly if you can sell some parts and make some dollars at the end of the day what does it matter how the thing got here? Especially as this machine is 40 plus years old I think it's time to build a bridge and get over it. (By the way, FYI, the equivalent machine imported into Australia via authorised channels is an L185. There are some subtle differences but 98% the same machine. Having said that this particular tractor is a little more unique and I've since discovered it's an L1501AC model which has this 'high tech' electronic equiped dash - very fancy in the day but a right royal pain in the butt with no documentation and no knowledge base and no parts available for it, that I can find, in Australia.)

If anyone knows anything about this model, or has any insight then I'd love to hear from you.

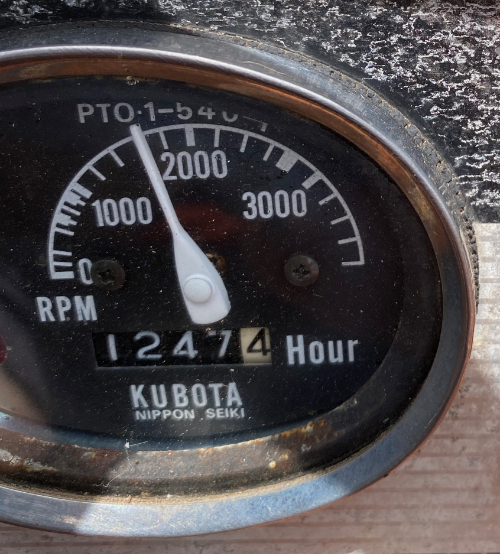

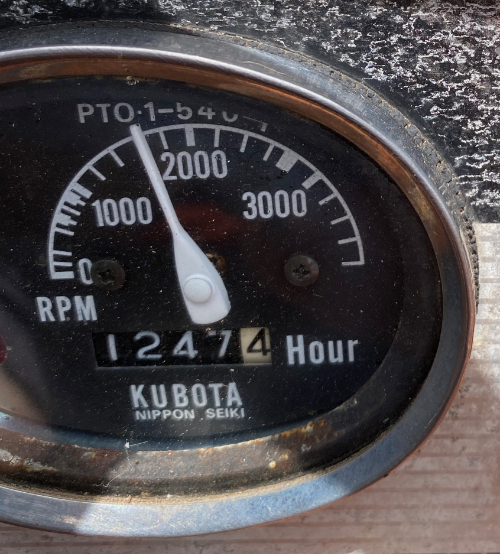

Anyway time goes on and I track down some places you can buy supplies, things like air, oil and fuel filters - pretty handy maintenance items. I found a guy selling a compatible oil pressure sensor, that sorted the oil light on the dash - I assumed the pressure was ok as everything appeared to be working ok but a red light on the dash is always a concern. So no red lights on the dash was a relief. My next annoyance was the tacho/hour meter not working, sure I can live without it but it's kind of nice having it working and it's amazing how quickly the hours get away from you so having the hour meter working makes knowing when maintenance needs to be done so much easier. After living without the tacho/hour meter for six years or so I discovered the drive gear is still available new. In the USA you can find Kubota dealers with online parts ordering, which includes exploded drawings of the various components of the tractor. Knowing that the L1501 was essentially the same as an L185 I was able to obtain a Kubota part number, plus I printed out the parts drawing and took that along to my local Kubota dealer. There I discovered the Kubota part number was a match for Australia's system, so that suggests Kubota have one numbering system globally - a very sensible thing. Eight weeks later, as the part had to come from Japan, I fitted the new drive gear and bingo I now have a working tacho/hour meter, yes!!

Awesome, it's so good having things working and informing you of what's going on with the tractor - love it!!

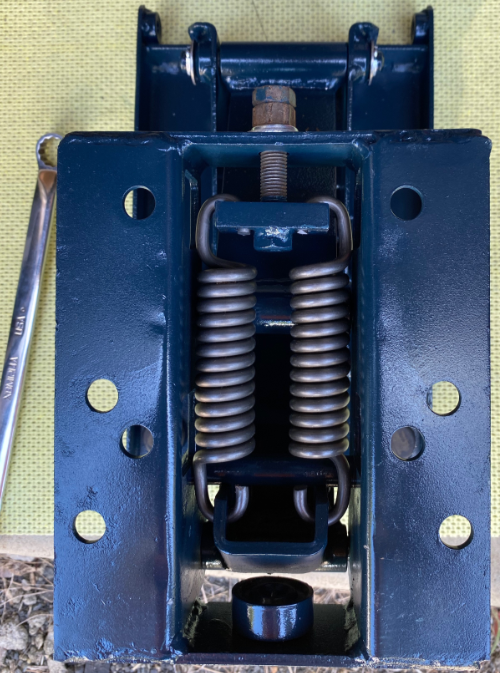

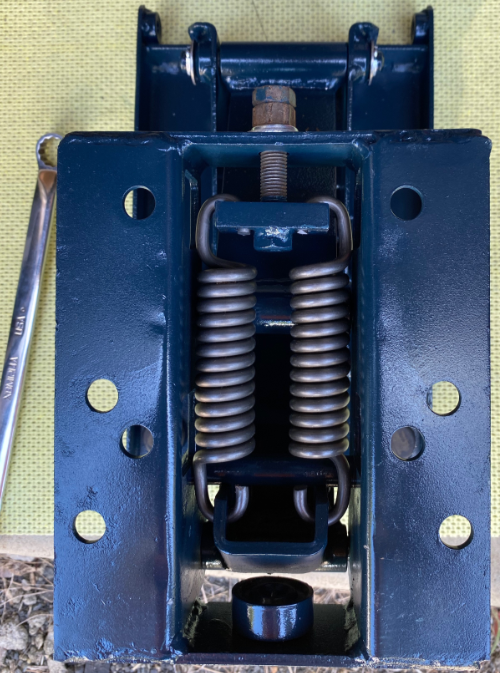

Now I'm on a roll. Not long after I bought the tractor one of the seat suspension springs broke so the past six years has been a bit of a rough ride bumping up and down on the chassis. I thought perhaps I can find a suitable spring at the Kubota dealer, I was thinking a Bear & Co. part or the like. Well there was anything even close to what I needed so the parts guy said 'let me look up the original part and see if it's available'. Well blow me down they have 4 in Melbourne, give me two please I said - for sure if I only replace one the other one will break 30 seconds after putting it all back together. And while I've got the seat suspension apart why not sand blast it and give it a fresh coat of Kubota blue, sounds like a plan.

Now for the new springs.

Some stainless washers and new split pins and we're good to go.

Sure the seat is old and dodgy but at least now I have suspension. I can't believe how much better driving the tractor is now that I have a working seat. Fortunately I don't use it day in and day out so it's never been that bad, just a bit on the rough side…

Now confident that I could obtain parts I decided to tackle another issue which had been annoying me since purchasing the tractor, the front right wheel had a wobble which I suspected was due to a dodgy bearing or two. Off to the Kubota dealer armed with drawings and part number where I was able to order all the parts I needed, oil seals, O rings, gaskets etc. The bearings I obtained from a bearing supplier as the price was a good deal lower than genuine Kubota bearings.

The front right 4WD unit, not too bad for 45 years of wear and tear.

As suspected the problem was the top bearing. Hmmm that's definitely had it, but in actual fact it's not as bad as I expected given the age of the tractor.

What did surprise me was what I discovered about the top bevel case. There's no drain or fill plug, so how do you lubricate the bearings and gears? All the bearings are open type so without lubrication they are destined to fail, not if but a matter of when. There was evidence of some lubrication on the bevel gear attached to the shaft from the diff but it remains a concern in terms of the design. All I can think of is that perhaps the intention is that in the usual service of the tractor, every xxx hours you're meant to pull the drive unit off, check and lubricate the gears. Based on what I found I think it's unlikely this had happened anytime since this tractor left the factory. That being the case it was in much better condition that it really should be - thank goodness for small mercies.

I'll need to come up with a solution of some sort before putting the drive unit back together. First thought is to replace the open bearings with sealed bearings, that's got to be a better option in this situation. I talked with a friend who works for a bearing company, he suggest using NLGI 0 grease to lubricate the gears, being a soft grease it'll flow nicely to protect the gears but shouldn't put any pressure on the seals. The Kubota guys suggested 80/90 gear oil, which is what's used in the lower axle housing but there's no evidence of oil ever being used in this housing and definitely no drain or fill plug. Oil doesn't feel right, so I've ordered some NLGI 0 grease. Only problem is the smallest container I can buy is 20Kg - anyone need some NLGI 0 grease? I need around 400g to do both units, so plenty left over. I did try to find an Ag service business which might have a container of the grease and be willing to sell me half a kilo but alas I couldn't find anyone willing to do so. (Happy to sell me 20Kg but not a scoop from their drum in the workshop.)

I decided to use three sealed bearings and three open bearings, partly because my friend who works for the bearing company had already supplied me the six bearings needed for the right hand unit and they were all open bearings. With the decision to install sealed bearings in the top bevel gear case and the upper bearing in the axle case I needed to buy more bearings.

The bearings are easily obtainable from any bearing supplier. Each drive unit needs a 6204 bearing for the top, that's the one in the pic above - which has clearly failed. The lower bearing in the bevel gear case is a 6206 as is the top bearing of the axle case. The lower bearing in the axle case is a 6008. Then for the axle itself there's a 6206 and a 6207. So in summary you need the following bearings for each drive unit:

1 x 6204

3 x 6206

1 x 6207

1 x 6008

I was pleasantly surprised with what I found when I pulled the axel/axle flange from the axle case, three of the four bearings in the axle case were in really good condition. The top bearing was slightly worn and that makes sense as it butts up agains the bevel gear case and therefore took more of a pounding as the bearings above failed.

Nice, that's looking really good. With the right drive unit apart I realised there was another gasket I needed so I ordered two, they'll be a week away. That being the case I thought I'd tackle the left drive unit and get both done at the same time. Originally I was just going to rebuild the right drive unit as it appeared to be the one with the biggest wobble. Well to my surprise the left drive unit was in much worse shape, so I'm glad I pulled it apart when I did otherwise it might have been curtains for that unit given what I'm planning once the rebuild is done.

First signs of trouble, lots of oily gunk on the axle.

Next worrying sign, no oil coming out…

Yikes, what will I find inside?

Oh dear, that's ugly. Every bearing is knackered, but at least there was a smidge of moisture in there which I guess means things could have been worse. A lot of cleaning up to do on this drive unit, and given the wear some shim adjusting for the backlash will be mandatory.

Closing in on the rebuild, waiting on a couple of bits to arrive but cleaned up, wire brushed, sanded and repainted they're looking pretty spiffy.

Left hand unit

Right hand unit

Hopefully they'll be back on the tractor in the next week or so.

In the meantime I'll deal with the rather bent tie rod, looks like a previous owner/driver tried some rock jumping…

It's bent in at least two main directions and rubbing up against the diff housing.

After some wrestling on the press.

I think that will do, a lot better now. Didn't want to push my luck or over work the steel so will leave it at that. I have new tie rod ends so next job is to remove the old tie rod ends, give it a clean, sand and fresh coat of paint before fitting the new tie rod ends.

The parts arrived and everything has been refitted, scooped some of the NLGI 0 grease into the top bevel housing and then back onto the tractor.

Next challenge…

When connecting up the draglink, moving the steering wheel to align the tiered with the link arm on the left front drive unit I notice the whole front axle assembly moved forward and back approximately 12mm - as I moved the steering wheel to the left or right. This can't be right, yikes. I posted my dilemma on Orange Tractor Talks and the thinking was one of the bushes or thrust washers is damaged and allowing the axle to move. Perhaps the diff assembly had been apart at some point and not put back together correctly - given some of the things I've had to repair since I purchased the tractor this would not be an unreasonable assumption.

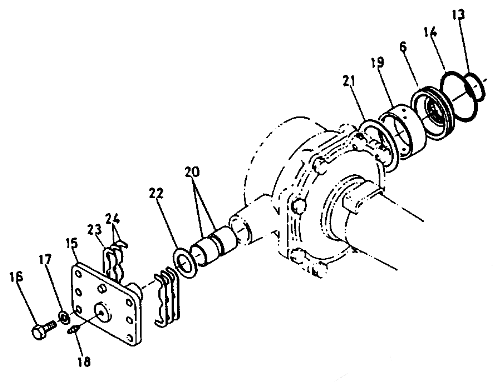

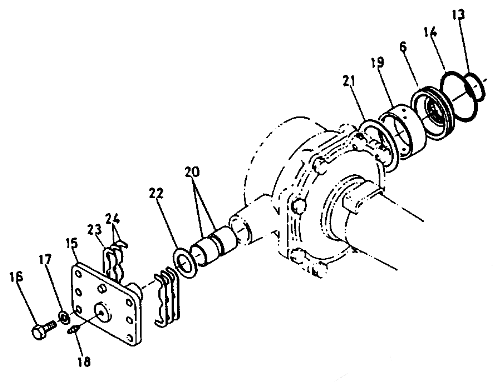

I went to the local Kubota guys to order two bushes, part number 37650-44630 (20 in the diagram), and a thrust collar, part number 37650-44640 (22 in the diagram). Both parts have been discontinued but there was one of the thrust collars still in stock - so I ordered that right away. I tracked down a couple of the bushes at Pillar Surplus in the USA and they kindly shipped the parts to me - the freight cost as much as the bushes.

While I waited for the parts to arrive I decided to get stuck into the slashing which needed to be done - and the reason I rebuilt the front drive units. I hadn't used the slasher for around four years so I gave it a clean up and check over before getting stuck in.

This was my test patch before heading out to tackle a couple of acres of more challenging terrain.

And it now looks like this:

Excellent!! I'm working toward better fire management and better visibility of snakes - that's just as important… Those Eastern Browns are just plain nasty.

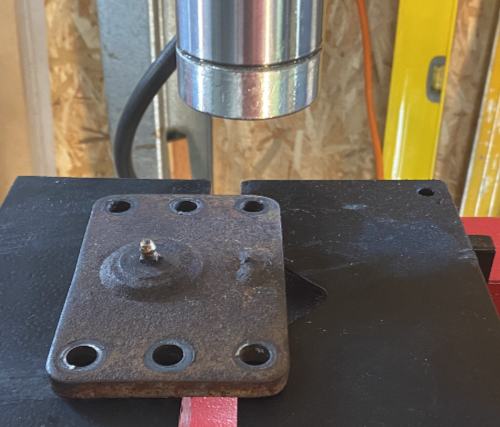

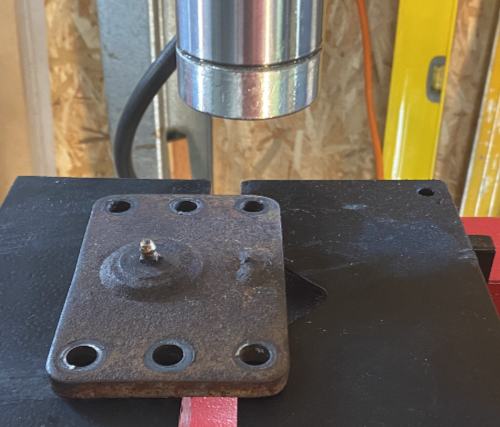

The bushes finally arrived and today, 15th April 2023, I thought I'd pull the front diff apart and see if I could fix the movement problem. I found it issue was not the bushes or the thrust washer but rather the diff pivot pin plate. Somehow a previous owner/driver has managed to bend it, so it wasn't holding pressure on the diff and preventing it from moving. It doesn't look quite as bad as it was in the pics but they give you the idea.

Some manoeuvring in the hydraulic press and the pivot pin was looking much straighter. I will see if it's possible to buy a new unit but in the meantime the straightening will suffice.

The tractor is back together and the axle no longer moves forward and back with the turning of the steering wheel - another win.

But that was over 40 years ago, the farm was sold back in the 1970s and my grandparents have long left this mortal coil. However I'm now living close to where the farm was and have my own little piece of paradise in the Brisbane Valley, it's not a lot but it's my lot. The block was really just a small slice of a paddock when I bought it in 2016, with grass over a meter tall and scrubby trees which I suspect had been seeded by birds flying over. The block is quite steep and the paddock grass was thick, woody and tough to cut so I decided to buy a tractor - just the excuse I needed to fulfil a boyhood dream. The block would have been too much for a typical ride on mower to handle and, I rationalised, the range of implements I could add to the tractor made it much more useful and more logical choice. Enter Rupert, my Kubota L1501DT tractor. (I named it Rupert because it looks like it comes from the Isle of Sodor.)

When I bought the tractor I was told everything works, "I just got the indicators working recently." In reality that was not so true, the indicators didn't work, although that doesn't bother me. The things which didn't work but which I really wanted to were: the tacho/hour meter, the charge light was always on, as was the oil warning light. This particular machine seems rather unique in Australia as the writing on the dash is in Japanese and the controls/layout are quite different from just about every other L1501 I've seen, plus no-one I've spoken to has ever seen one the same - not inspiring when you're trying to troubleshoot problems. Rather than a lever to the right of the seat to operate the three point linkage this model has a toggle switch on the dash for raising/lowering. Annoyingly the fuse for this switch kept blowing so I soon learnt to carry a box of spare fuses in my pocket just to get through the two hours of slashing I needed to do.

I searched for wiring diagrams, without much joy, and eventually thought I'd remove the fuse box and check all the wiring. It was then I discovered the fusebox had been installed upside down - this answered a few questions right away. I suspect the incorrect installation was leading to some shorting and once installed the correct way around my blown fuse problem disappeared, thankfully. However later the mechanism failed to operate at all, I traced the problem to a bad earth and resolved the issue by running a new earth wire to the rear of the tractor - nothing like dodgy wiring to ruin your day. By the way it was a bad earth issue with the wiring to the alternator causing the charge light to always be on, sorted that one early on to avoid draining the battery unnecessarily. Resolving some of the other issues meant buying some new parts and it was then that I discovered my L1501DT is a 'grey import', meaning this was not a model Kubota Australia imported into the country and their policy is not to support or supply parts to grey import tractors. I didn't know anything about this 'issue' when I bought the tractor, I just went looking and bought something which suited my needs. As far as I was concerned surly if you can sell some parts and make some dollars at the end of the day what does it matter how the thing got here? Especially as this machine is 40 plus years old I think it's time to build a bridge and get over it. (By the way, FYI, the equivalent machine imported into Australia via authorised channels is an L185. There are some subtle differences but 98% the same machine. Having said that this particular tractor is a little more unique and I've since discovered it's an L1501AC model which has this 'high tech' electronic equiped dash - very fancy in the day but a right royal pain in the butt with no documentation and no knowledge base and no parts available for it, that I can find, in Australia.)

If anyone knows anything about this model, or has any insight then I'd love to hear from you.

Anyway time goes on and I track down some places you can buy supplies, things like air, oil and fuel filters - pretty handy maintenance items. I found a guy selling a compatible oil pressure sensor, that sorted the oil light on the dash - I assumed the pressure was ok as everything appeared to be working ok but a red light on the dash is always a concern. So no red lights on the dash was a relief. My next annoyance was the tacho/hour meter not working, sure I can live without it but it's kind of nice having it working and it's amazing how quickly the hours get away from you so having the hour meter working makes knowing when maintenance needs to be done so much easier. After living without the tacho/hour meter for six years or so I discovered the drive gear is still available new. In the USA you can find Kubota dealers with online parts ordering, which includes exploded drawings of the various components of the tractor. Knowing that the L1501 was essentially the same as an L185 I was able to obtain a Kubota part number, plus I printed out the parts drawing and took that along to my local Kubota dealer. There I discovered the Kubota part number was a match for Australia's system, so that suggests Kubota have one numbering system globally - a very sensible thing. Eight weeks later, as the part had to come from Japan, I fitted the new drive gear and bingo I now have a working tacho/hour meter, yes!!

Awesome, it's so good having things working and informing you of what's going on with the tractor - love it!!

Now I'm on a roll. Not long after I bought the tractor one of the seat suspension springs broke so the past six years has been a bit of a rough ride bumping up and down on the chassis. I thought perhaps I can find a suitable spring at the Kubota dealer, I was thinking a Bear & Co. part or the like. Well there was anything even close to what I needed so the parts guy said 'let me look up the original part and see if it's available'. Well blow me down they have 4 in Melbourne, give me two please I said - for sure if I only replace one the other one will break 30 seconds after putting it all back together. And while I've got the seat suspension apart why not sand blast it and give it a fresh coat of Kubota blue, sounds like a plan.

Now for the new springs.

Some stainless washers and new split pins and we're good to go.

Sure the seat is old and dodgy but at least now I have suspension. I can't believe how much better driving the tractor is now that I have a working seat. Fortunately I don't use it day in and day out so it's never been that bad, just a bit on the rough side…

Now confident that I could obtain parts I decided to tackle another issue which had been annoying me since purchasing the tractor, the front right wheel had a wobble which I suspected was due to a dodgy bearing or two. Off to the Kubota dealer armed with drawings and part number where I was able to order all the parts I needed, oil seals, O rings, gaskets etc. The bearings I obtained from a bearing supplier as the price was a good deal lower than genuine Kubota bearings.

The front right 4WD unit, not too bad for 45 years of wear and tear.

As suspected the problem was the top bearing. Hmmm that's definitely had it, but in actual fact it's not as bad as I expected given the age of the tractor.

What did surprise me was what I discovered about the top bevel case. There's no drain or fill plug, so how do you lubricate the bearings and gears? All the bearings are open type so without lubrication they are destined to fail, not if but a matter of when. There was evidence of some lubrication on the bevel gear attached to the shaft from the diff but it remains a concern in terms of the design. All I can think of is that perhaps the intention is that in the usual service of the tractor, every xxx hours you're meant to pull the drive unit off, check and lubricate the gears. Based on what I found I think it's unlikely this had happened anytime since this tractor left the factory. That being the case it was in much better condition that it really should be - thank goodness for small mercies.

I'll need to come up with a solution of some sort before putting the drive unit back together. First thought is to replace the open bearings with sealed bearings, that's got to be a better option in this situation. I talked with a friend who works for a bearing company, he suggest using NLGI 0 grease to lubricate the gears, being a soft grease it'll flow nicely to protect the gears but shouldn't put any pressure on the seals. The Kubota guys suggested 80/90 gear oil, which is what's used in the lower axle housing but there's no evidence of oil ever being used in this housing and definitely no drain or fill plug. Oil doesn't feel right, so I've ordered some NLGI 0 grease. Only problem is the smallest container I can buy is 20Kg - anyone need some NLGI 0 grease? I need around 400g to do both units, so plenty left over. I did try to find an Ag service business which might have a container of the grease and be willing to sell me half a kilo but alas I couldn't find anyone willing to do so. (Happy to sell me 20Kg but not a scoop from their drum in the workshop.)

I decided to use three sealed bearings and three open bearings, partly because my friend who works for the bearing company had already supplied me the six bearings needed for the right hand unit and they were all open bearings. With the decision to install sealed bearings in the top bevel gear case and the upper bearing in the axle case I needed to buy more bearings.

The bearings are easily obtainable from any bearing supplier. Each drive unit needs a 6204 bearing for the top, that's the one in the pic above - which has clearly failed. The lower bearing in the bevel gear case is a 6206 as is the top bearing of the axle case. The lower bearing in the axle case is a 6008. Then for the axle itself there's a 6206 and a 6207. So in summary you need the following bearings for each drive unit:

1 x 6204

3 x 6206

1 x 6207

1 x 6008

I was pleasantly surprised with what I found when I pulled the axel/axle flange from the axle case, three of the four bearings in the axle case were in really good condition. The top bearing was slightly worn and that makes sense as it butts up agains the bevel gear case and therefore took more of a pounding as the bearings above failed.

Nice, that's looking really good. With the right drive unit apart I realised there was another gasket I needed so I ordered two, they'll be a week away. That being the case I thought I'd tackle the left drive unit and get both done at the same time. Originally I was just going to rebuild the right drive unit as it appeared to be the one with the biggest wobble. Well to my surprise the left drive unit was in much worse shape, so I'm glad I pulled it apart when I did otherwise it might have been curtains for that unit given what I'm planning once the rebuild is done.

First signs of trouble, lots of oily gunk on the axle.

Next worrying sign, no oil coming out…

Yikes, what will I find inside?

Oh dear, that's ugly. Every bearing is knackered, but at least there was a smidge of moisture in there which I guess means things could have been worse. A lot of cleaning up to do on this drive unit, and given the wear some shim adjusting for the backlash will be mandatory.

Closing in on the rebuild, waiting on a couple of bits to arrive but cleaned up, wire brushed, sanded and repainted they're looking pretty spiffy.

Left hand unit

Right hand unit

Hopefully they'll be back on the tractor in the next week or so.

In the meantime I'll deal with the rather bent tie rod, looks like a previous owner/driver tried some rock jumping…

It's bent in at least two main directions and rubbing up against the diff housing.

After some wrestling on the press.

I think that will do, a lot better now. Didn't want to push my luck or over work the steel so will leave it at that. I have new tie rod ends so next job is to remove the old tie rod ends, give it a clean, sand and fresh coat of paint before fitting the new tie rod ends.

The parts arrived and everything has been refitted, scooped some of the NLGI 0 grease into the top bevel housing and then back onto the tractor.

Next challenge…

When connecting up the draglink, moving the steering wheel to align the tiered with the link arm on the left front drive unit I notice the whole front axle assembly moved forward and back approximately 12mm - as I moved the steering wheel to the left or right. This can't be right, yikes. I posted my dilemma on Orange Tractor Talks and the thinking was one of the bushes or thrust washers is damaged and allowing the axle to move. Perhaps the diff assembly had been apart at some point and not put back together correctly - given some of the things I've had to repair since I purchased the tractor this would not be an unreasonable assumption.

I went to the local Kubota guys to order two bushes, part number 37650-44630 (20 in the diagram), and a thrust collar, part number 37650-44640 (22 in the diagram). Both parts have been discontinued but there was one of the thrust collars still in stock - so I ordered that right away. I tracked down a couple of the bushes at Pillar Surplus in the USA and they kindly shipped the parts to me - the freight cost as much as the bushes.

While I waited for the parts to arrive I decided to get stuck into the slashing which needed to be done - and the reason I rebuilt the front drive units. I hadn't used the slasher for around four years so I gave it a clean up and check over before getting stuck in.

This was my test patch before heading out to tackle a couple of acres of more challenging terrain.

And it now looks like this:

Excellent!! I'm working toward better fire management and better visibility of snakes - that's just as important… Those Eastern Browns are just plain nasty.

The bushes finally arrived and today, 15th April 2023, I thought I'd pull the front diff apart and see if I could fix the movement problem. I found it issue was not the bushes or the thrust washer but rather the diff pivot pin plate. Somehow a previous owner/driver has managed to bend it, so it wasn't holding pressure on the diff and preventing it from moving. It doesn't look quite as bad as it was in the pics but they give you the idea.

Some manoeuvring in the hydraulic press and the pivot pin was looking much straighter. I will see if it's possible to buy a new unit but in the meantime the straightening will suffice.

The tractor is back together and the axle no longer moves forward and back with the turning of the steering wheel - another win.